Dry vs. Wet Contacts

In industrial automation, understanding the difference between dry and wet contacts is critical for designing safe, reliable, and efficient control panels. While the terms might sound simple, choosing the right type of contact impacts how circuits are wired, how devices communicate, and how systems perform over time.

In this article, we’ll break down what dry and wet contacts are, how they’re used in automation, their advantages, drawbacks, and best practices for selecting the right option.

What Are Dry and Wet Contacts?

Dry Contacts (Potential-Free Contacts)

- Dry contacts are mechanical switches or relays that do not supply their own voltage or current.

- An external power source is required to operate them.

- They act as an interface between devices (like sensors or actuators) and a PLC, providing electrical isolation between control and power circuits.

Wet Contacts (Powered Contacts)

- Wet contacts have a built-in power source and share power with the control circuit.

- They combine power and signal into one connection, simplifying wiring and integration.

- While convenient, wet contacts limit felxibility since they provide only their preset voltage/current.

Applications of Dry Contacts

Dry contacts are widely used where safety, isolation, and flexibility are top priorities:

- Relays and Switches - Provide isolation between low-voltage control circuits and high-power devices

- Control Panels - Common in motor control circuits, where a dry contact relay isolates a control switch from a motor starter.

- PLCs - Offer separation between inputs and outputs, ensuring precise control and protection from surges.

- Noise Reduction - Since they don't carry inherent voltage, dry contacts reduce the resk of electrical noise affecting PLC signals.

- Voltage Flexibility - Allow designers to choose the appropriate external voltage and current for their specific application.

Applications of Wet Contacts

Wet contacts are often chosen for simplicity and ease of integration:

- Integrated Sensors - Devices such as proximity switches and temperature monitors use wet contacts to transmit both signal and power.

- Actuators and Load Control - Share a common power source, reducing wiring needs and simplifying installation.

- Multi-Sensor Systems - Multiple sensors can share a single power supply through wet contacts, cutting down on extra hardware.

- Troubleshooting and Maintenance - Fewer connections make systems easier to wire and service.

Best Practices

- Assess Your Application - Identify whether isolation, simplicity, or voltage flexibility is the main priority.

- Check Specifications - Always consult manufacturer data sheets for compatibility and performance details.

- Plan for Maintenance - Keep in mind that dry contacts are often easier to troubleshoot compared to wet contacts.

- Prioritize Safety - For safety-critical applications. dry contacts are usually the better option due to their isolation capabilities.

Conclusion

Dry and wet contacts each serve essential roles in industrial automation. Dry contacts offer isolation, flexibility, and protection, making them a great choice for circuits that require safety and precision. Wet contacts, on the other hand, simplify wiring and reduce hardware needs, making them ideal for integrated systems where convenience and efficiency are priorities. By understanding their strengths, limitations, and applications, you can choose the right contact type to optimize your control panels and ensure safe, reliable performance.

Transcript From Video:

[0m:00s] Hey, I'm Mitchell, and welcome to another video in the RSP Education Series. Today, we're going to talk about the basics and applications of dry and wet contacts within industrial automation. Understanding the difference between wet and dry contacts is key to wiring your control panels correctly. If you want to know how they work, this video is for you. And if you like this kind of content and want more educational videos, please like and subscribe. This video is for educational purposes only. Always consult a professional for your specific application. RSP Supply is not liable for any misuse of the information. With that said, let’s get right into it.

[1m:00s] In this video, we’ll explore the basics, including what dry or potential-free contacts are and what wet or powered contacts are. We’ll look at how they’re used in relays, PLCs, safety systems, and sensors, and discuss their advantages. You’ll learn when to choose dry contacts for isolation or wet contacts for simplicity, plus a few best practices for wiring and maintaining each type. So, let’s start with the fundamentals. Dry contacts are potential-free contacts, meaning they require an external power source to operate. They are mechanical switches or relays that don’t carry any built-in voltage or current. Instead, they act as an interface between external devices like sensors or actuators and the PLC. Wet contacts, on the other hand, have a built-in power source that they share with the control circuit.

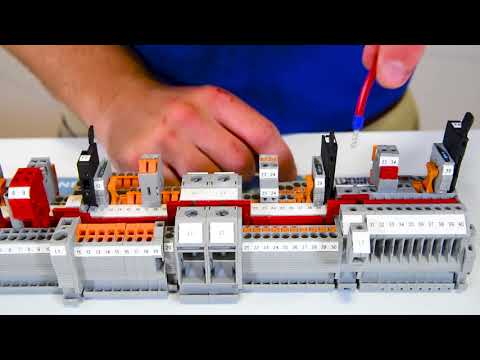

[2m:10s] Because dry contacts require an external power source, they’re ideal for circuit isolation. Wet contacts simplify wiring within integrated systems but have certain limitations in flexibility. Dry contacts play a big role in safety, reliability, and versatility across many industrial applications. You’ll see them used with relays, switches, and control circuits. In relay circuits, dry contacts provide isolation between control and power circuits, allowing different voltage levels to coexist safely and efficiently. They’re also common in control panels for industrial automation, such as motor control circuits. For example, a dry contact relay can isolate a control switch from a high-power motor starter, protecting the low-voltage circuit while safely activating the motor.

[3m:20s] PLCs also rely heavily on dry contacts to separate input and output circuits. This ensures precise control and protection from power surges while preventing interference or feedback from external circuits. Because dry contacts don’t carry their own voltage, they help reduce the risk of noise affecting PLC input or output signals. Wet contacts, meanwhile, simplify automation systems by combining power and signal into a single connection. They reduce interfaces between actuators and control systems, which helps cut down on wiring errors and makes troubleshooting easier. You’ll often find wet contacts used in integrated sensor systems like proximity switches and temperature monitors, where they send signals and provide power simultaneously.

[4m:10s] Wet contacts can also allow multiple sensors to share a single power source, reducing the need for extra power supplies or converters. In actuators and load control systems, they greatly simplify the control circuit by sharing a common power source, which reduces installation time and maintenance. A valve actuator with wet contact outputs can directly receive commands and power from a controller without requiring separate wiring for signals and power lines. In short, wet contacts are a practical choice for integrated systems because they simplify wiring, reduce the number of components, and make installation and maintenance easier.

[5m:10s] So, how do you choose between the two? Dry contacts offer strong isolation, support multiple voltage levels, and are the go-to choice when circuit separation and voltage versatility are important. However, they require an external power source and involve more complex wiring. Wet contacts, on the other hand, provide simplified wiring and are cost-effective for integrated systems but have a limited voltage range and are less suited for safety-critical applications. Always assess your system’s isolation, voltage, and safety requirements before choosing. Check manufacturer specs and plan maintenance accordingly. Dry contacts are generally easier to troubleshoot, while wet contacts save time on installation. To conclude, understanding the roles of dry and wet contacts is essential for designing efficient and reliable automation systems. Each type has its place depending on the needs of your control panel and system design. For a full line of hundreds of thousands of industrial and automation products, visit RSPSupply.com — the internet’s top source for industrial hardware and education.