.

What is a Switchgear? Industrial Power Systems Explained

In industrial power systems, two critical works together to deliver safe and reliable energy; switchgear and transformers. If you’ve ever wondered how industrial operations manage massive amounts of power while keeping workers and equipment safe, understanding switchgear is the first step.

What is Switchgear?

Switchgear is the term used for a collection of devices that control, protect, and isolate electrical equipment. At its core, switchgear ensures that power flows efficiently through an electrical system while preventing faults such as overcurrent's, short circuits, and arc flash events from disrupting operations. Without switchgear, live power systems would be unsafe to operate and nearly impossible to maintain.

Key Functions of Switchgear

-

Control – turns electrical circuits on or off to regulate the flow of power.

-

Protection – guards against overloads, short circuits, and other electrical faults by disconnecting affected circuits.

-

Isolation – safely disconnects parts of the system for maintenance or repairs.

These functions keep industrial power systems safe, reliable, and efficient.

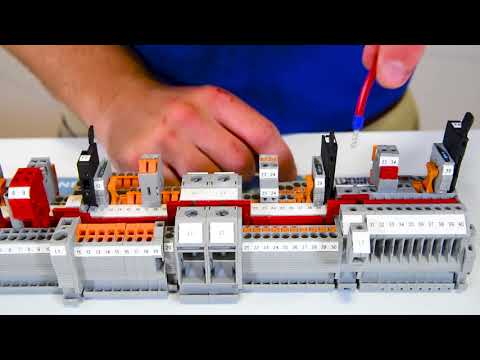

Major Components of Switchgear

Switchgear is made up of several critical components that work together to protect and manage power distribution.

- Circuit Breakers - automatically interrupt current during a fault.

- Disconnect Switches - manually or remotely isolate circuits for safe maintenance.

- Relays - monitor current and voltage; trigger breakers if faults or imbalances are detected.

- Bus Bars - conduct and distribute electrical power within the switchgear assembly.

- Fuses - melt under excessive current flow, providing overcurrent protection.

- Current & Voltage Transformers - measure system parameters to support monitoring and protection systems.

Protection Mechanisms in Switchgear

Modern switchgear includes advanced safety features to protect both workers and equipment like Arc Flash Mitigation which uses fast-acting relays and arc-resistant enclosures to reduce risks from arc events. As well as Selective Coordination, which ensures only the faulted circuit is disconnected, minimizing disruption to other operations.

Types of Switchgear

Switchgear is categorized by both voltage level and arc-interrupting medium.

By Voltage:

-

Low Voltage (LV): Up to 1 kV, common in small commercial or residential systems.

-

Medium Voltage (MV): 1 kV to 36 kV, typically used in industrial settings.

-

High Voltage (HV): Above 36 kV, used in utility-scale power distribution.

By Arc-Interrupting Medium:

-

Air-Insulated Switchgear (AIS): Cost-effective but requires more space.

-

Gas-Insulated Switchgear (GIS): Compact and efficient, using SF₆ gas for insulation.

-

Vacuum Circuit Breakers (VCB): Use a vacuum to extinguish arcs, offering durability and low maintenance.

Why Switchgear Matters

Switchgear is the backbone of industrial automation and power distribution systems. By controlling power flow, isolating faults, and protecting workers from dangerous events like arc flash, switchgear ensures industrial operations remain safe, efficient, and reliable.

Transcript From Videos:

[0m:00s] Hi, I’m Mitchell, and welcome to another video in the RSP Education Series! Today we’re going to talk about one of the two critical players in industrial power systems: switchgear, the other being transformers. Switchgear is essential for safe and reliable power systems. In this video, we’ll explore its key functions, components like circuit breakers and relays, and the various types of switchgear used in industrial automation. Stay tuned for our next video, where we’ll get into transformers and see how these two systems work together to power industrial operations efficiently. If you like this content and want more educational videos, please like and subscribe. Also, this video is for educational purposes only, consult a professional for your application. RSP Supply is not liable for misuse of this information.

[0m:55s] So, what is switchgear? Switchgear is a broad term used to describe a combination of devices that control, protect, and isolate electrical equipment. At its core, switchgear manages power flow within an electrical system and ensures that faults don’t disrupt operations or cause damage. Without switchgear, electrical systems cannot operate safely in live power systems due to the risk of overcurrents, short circuits, or arc flash events. Some key functions of switchgear include control, which turns circuits on or off as needed; protection, which safeguards systems against short circuits, overloads, and other electrical faults; and isolation, which allows for safe maintenance by disconnecting specific parts of the system.

[2m:00s] Let’s break down the major components that make up a switchgear assembly. Circuit breakers automatically interrupt current flow during a fault to protect the system. Disconnect switches are used to manually or remotely isolate circuits for safe maintenance. Relays monitor current entering and exiting the system, and if imbalances are detected that indicate faults, they trigger circuit breakers to disconnect the affected section. Relays also manage overcurrent conditions to prevent overheating or winding damage in transformers. Bus bars conduct power within the switchgear assembly and distribute it to various circuits. Fuses melt under excessive current flow, providing overcurrent protection. Current and voltage transformers measure system parameters and provide data for monitoring and protection systems. Modern switchgear also includes arc flash mitigation, such as fast-acting relays and arc-resistant enclosures to reduce the risk of injury or equipment damage. Arcs happen when breakers separate energized circuits and energy tries to maintain a connection, and arc mitigation prevents this from becoming dangerous.

[3m:25s] Another important concept is selective coordination, which ensures only the faulted circuit is isolated, minimizing disruption to other operations. This is achieved through precise relay settings and breaker configurations. Now, let’s look at the types of switchgear. They’re categorized based on voltage level, installation environment, and the medium used for insulation and arc interruption. Low-voltage switchgear handles up to 1 kilovolt and is commonly used in small commercial or residential systems. Medium-voltage switchgear ranges from 1 to 36 kilovolts and is often found in industrial settings. High-voltage switchgear, which operates above 36 kilovolts, is used in utilities and large-scale power distribution systems.

[4m:00s] Switchgear is also categorized by arc-interrupting medium — the material or method used to extinguish the electrical arc that forms when current flow is interrupted. The arc is a plasma discharge caused by high energy attempting to maintain continuity between separated contacts, and efficiently quenching this arc is critical to preventing equipment damage and ensuring safety. Common arc-interrupting mediums include air-insulated switchgear, which is cost-effective but space-intensive; gas-insulated switchgear, which is more compact and efficient and uses SF₆ gas for insulation; and vacuum circuit breakers, which use a vacuum for arc extinction and offer high durability with low maintenance. As we now understand, switchgear is a vital part of industrial automation. It ensures safe, efficient, and reliable power distribution. In the next video, we’ll discuss transformers and how they work together with switchgear to form the backbone of modern power systems. For a full line of switchgear and hundreds of thousands of other industrial products, visit our website. For more educational videos, go to RSPSupply.com — the internet’s top source for industrial hardware.