Industrial Instrumentation Basics

How do industrial systems know when to pump, mix, heat, or shut down all without human input? The answer is instrumentation. Instrumentation provides the measurements and feedback that keep processes safe, efficient, and fully automated. From oil refineries to water treatment plants, instrumentation connects the physical world to control systems, feeding data to PLCs, triggering actuators, and keeping operations running smoothly.

In this article, we’ll explore what instrumentation is, how it works, where it’s used, and why it serves as the foundation of automation.

What Is Industrial Instrumentation?

At its core, industrial instrumentation is about measuring, monitoring, and controlling processes in factories, plants, and industrial systems.

It works in three main steps:

- Sensors - Measure physical values such as temperature, pressure, level, or flow.

- Controllers - PLCs (Programmable Logic Controllers) or DCSs (Distributed Control Systems) process sensor data and make decisions.

- Actuators - Devices such as valves, motors, or pumps take action based on controller output.

For example, in a water treatment plant, a level sensor detects the water level in a tank. A PLC processes that data and decides when to turn on a pump. The pump motor (actuator) then starts, ensuring the process continues automatically.

Key Industries Using Instrumentation

Instrumentation is critical across nearly every major industry, including:

- Oil & Gas - Monitoring pipelines, pressure, and flow rates.

- Water Treatment - Controlling pumps, filtration, and chemical dosing.

- Pharmaceuticals - Maintaining strict environmental conditions like tempperature and humidity.

- Manufacturing - Automating assembly lines with sensors, robots, and control systems.

Common Signal Types

Instrumentation relies on signal standards to communicate measurements and commands between devices:

- 4-20 mA Current Loop - The most common standard, with 4 mA representing the minimum value and 20 mA the maximum. Highly resistant to electrical noise.

- 0-10 V Signal - An older, simpler method, though more prone to noise interference.

- HART Protocol - A digital signal transmitted over analog wiring, used for setup, calibration, and diagnostics.

Real-World Example: Water Treatment Plant

In an automated water treatment system:

- Sensors:

- Level sensors track water height in tanks.

- Flow sensors measure water movement.

- pH sensors monitor acidity and alkalinity.

- Controller:

- A PLC receives sensor data.

- It decides when to start pumps, adjust chemical dosing, or sound an alarm.

- Actuators:

- Motorized valves open to allow water flow.

- Pumps inject chemicals for pH balance.

- Alasrms notify operators if abnormal conditions occur.

Signals tie the system together: a level sensor might send a 4–20 mA signal (4 mA = empty tank, 20 mA = full tank), while the PLC sends a 0–10 V signal to control a dosing pump’s speed. Without instrumentation, operators would have to check every tank and valve manually—leading to inefficiency, risk, and human error.

Conclusion

Industrial instrumentation is the foundation of modern automation. It measures, monitors, and controls physical processes, ensuring industries like oil & gas, water treatment, pharmaceuticals, and manufacturing operate safely and efficiently.

By linking sensors, controllers, and actuators, instrumentation makes smart automation possible, and keeps our world running smoothly.

Transcript From Video:

[0m:00s] Hey, I’m Mitchell. Welcome to another video in the RSP Education Series. Today we’re going to talk about how industrial systems know when to pump, mix, heat, or shut down, all without human input. The answer is instrumentation. It allows machines to measure, monitor, and react in real time, keeping processes safe, efficient, and fully automated. From oil refineries to water treatment plants, instrumentation connects the physical world to control systems, feeding data to PLCs, triggering actuators, and keeping everything running smoothly. In this video, we’ll break down what instrumentation is, how it works, where it’s used, and why it is the foundation of automation. If you like this kind of content and want more educational videos, please like and subscribe. This video is for educational purposes only. Always consult a professional for your application. RSP Supply is not liable for any misuse of this information. With that said, let’s get right into it.

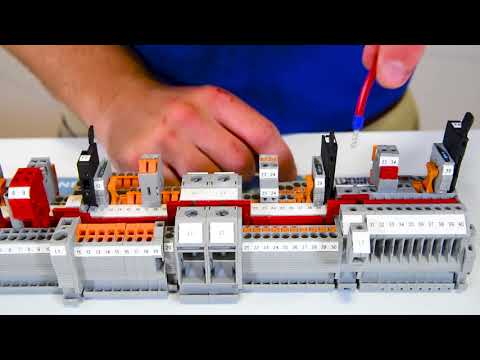

[1m:01s] Industrial instrumentation is about measuring, monitoring, and controlling processes in factories, plants, and industrial systems. Sensors collect data such as temperature, pressure, level, and flow. That data is sent to controllers like PLCs or distributed control systems, which make decisions. Actuators such as valves and motors then take action to keep everything within target ranges. Step by step: sensors measure a process variable, the controller evaluates that input against setpoints and logic, and the actuator executes the command to correct the process. Here is a simple example from a water treatment plant. A level sensor measures the water level in a storage tank. The PLC decides when to turn on a pump based on that level. The motor, acting as the actuator, starts pumping water until the level is restored. The same loop applies across countless tasks: temperature loops, pressure control, flow regulation, and chemical dosing. The result is continuous, automatic correction to keep processes stable and efficient.

[2m:54s] You will find instrumentation everywhere. Oil and gas uses it to monitor pipelines, pressure, and flow. Water and wastewater treatment relies on it for pumps, chemical dosing, filtration, and disinfection. Pharmaceutical production depends on precise temperature and humidity control. Manufacturing uses sensors and vision systems to automate assembly and quality checks. A quick note on common signal types: 4–20 mA is the most common analog standard, where 4 mA represents the minimum value and 20 mA the maximum. 0–10 V is also used, though it is generally more susceptible to electrical noise. HART overlays digital data on top of an analog signal, which is useful for configuration and diagnostics without running extra wires.

[4m:00s] Let’s expand the water treatment example with specific signals. The level transmitter sends a 4–20 mA signal to indicate tank level, where 4 mA equals empty and 20 mA equals full. A pH transmitter communicates over HART so technicians can calibrate and pull device diagnostics digitally over the same pair of wires. The PLC might output a 0–10 V signal to a variable speed chemical dosing pump to adjust feed rate. If the PLC detects low level, it starts the inlet pump. If pH drifts, it commands the dosing pump to correct it. If flow drops below a threshold, an alarm is generated to check for a blockage. All of this happens automatically based on programmed logic.

[5m:34s] Why this matters is simple. Without instrumentation, operators would need to manually check levels, temperatures, and flows, and then open valves or start motors by hand. That invites errors, slows response, and increases cost. With instrumentation, systems run 24/7 with minimal human input, improving safety, quality, uptime, and energy efficiency. To summarize: sensors are the eyes that detect process values, controllers are the brain that makes decisions, and actuators are the hands that take action. Signals like 4–20 mA, 0–10 V, and HART carry the information that ties it all together. This is the core of industrial automation across water, oil and gas, pharma, and manufacturing. In our next video, we will go deeper into signal types, selecting the right sensors, and designing more efficient systems. For hundreds of thousands of other industrial automation products, visit rpsupply.com, the internet’s top source for industrial hardware.