Acceptable_Grounding_Electrode_Systems__Materials_Grounding_Series_(Part_10).pdf

Transcript:

[0m:4s] Hi I'm Josh Bloom, welcome to another video in the RSP Supply education series. If you find that these videos are helpful to you, it certainly helps us out if you could give us a big thumbs up and subscribe to our channel.

[0m:15s] In today's video, we are going to continue on in our series in which we are discussing the basics of electrical grounding.

[0m:22s] In our last video, we talked about some of the different grounding electrode systems that are used in various electrical applications.

[0m:30s] If you have not already seen that video or any of the other videos in this series, we encourage you to go back and watch them as they can provide valuable information that will better assist you in understanding some of the concepts that will be discussed today.

[0m:46s] For the purpose of this video, we want to talk briefly about some of the more common and acceptable electrode systems and materials that can be used.

[0m:56s] Keep in mind that the systems and materials that we mentioned today are all NEC approved provided that they are installed and bonded correctly.

[1m:7s] In almost all electrical grounding systems, a variety of materials can be used.

[1m:14s] The most common material in these types of systems is copper because of its low impedance and its ability to dissipate electrical faults quickly and effectively.

[1m:25s] Other metallic materials are also very common,

[1m:29s] such as a wide variety of steel, iron, aluminum and many other options.

[1m:36s] All of these conductive materials can be used in the various electrode systems that we will discuss.

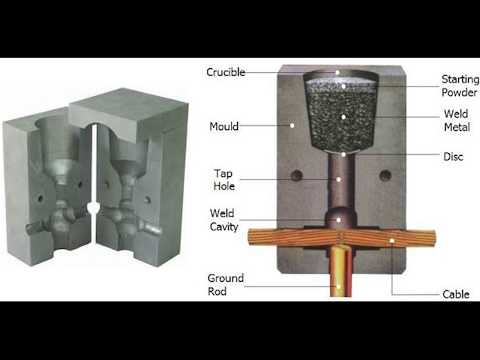

[1m:42s] First and probably the most common electrode grounding system is the ground rod or ground pipe.

[1m:50s] This rod is to be no less than eight feet in length and should come in direct contact with the soil. The more conductive the rod or pipe is the better your grounding system will perform.

[2m:1s] There are many different types of grounding rods and installation methods because of the effectiveness and popularity of this grounding electrode system.

[2m:10s] Next is the use of metal underground water piping as a grounding electrode.

[2m:17s] It is required that this pipe be in direct contact with the soil for at least 10 feet.

[2m:23s] It is also required a supplementary ground rod be used with this type of system in order to meet NEC requirements.

[2m:32s] Next is the ground ring which we discussed in our last video. A ground ring is simply conductive material such as copper that surrounds any given structure. It is required that the wire that is used be no smaller than two gauge wire, and that the wire is buried at least two and a half feet below the surface.

[2m:51s] There are other grounding techniques that can be used with this method to increase its overall effectiveness.

[2m:58s] Next would actually be using the metal frame of the structure or building that is being protected.

[3m:4s] It is required that when implementing this application, the metal frame have at least 10 feet of continuous contact

[3m:12s] with the soil in order to meet NEC requirements. It is recommended that bonding between different points of the structure occur in order to increase the effectiveness of this type of system.

[3m:25s] In regards to the next method, which we also mentioned in our last video, the use of concrete encased electrodes, or Ufer grounds, are also acceptable. In order for this type of electrode to meet NEC standard, it must be encased in at least two inches of concrete,

[3m:42s] and that concrete should have direct soil contact. Also, the electrode should be located near the bottom of the concrete foundation, and the conductor should be no less than 20 feet long, and no smaller than four gauge wire.

[3m:55s] Lastly, we want to talk about plate electrodes. Plate electrodes should be made from any highly conductive material and should always be in direct contact with surrounding soil. It is not uncommon to see these types of electrodes to be used to supplement other grounding systems, but not necessarily by themselves. If iron or steel is being used, the plate should be no less than one quarter inch thick.

[4m:24s] These electrodes need to be installed no less than two and a half feet below the surface to ensure proper Earth grounding.

[4m:32s] In cases where the frost line falls below that depth, the electrodes will need to be installed at a deeper level. As you can see, there are several different types of electrode materials and systems that can be used which can effectively provide safe and efficient grounding for your specific situation.

[4m:52s] For a full line of grounding equipment and thousands of other products, please go to our website. For more information or other educational videos, go to RSPSupply.com, the Internet's top source for industrial hardware. Also, don't forget: like and subscribe.