Why Do We Use Safety Relays?

- Implementing various safety functions — commonly in plant environments

- Commonly used with other safety relays

- Each relay will monitor one specific function

- Contacts can be open or closed, like a normal relay

- Electronic evaluation and control outputs based on evaluations

- Can be fully electronic

- Will still function if device fault occurs

- Redundant features help overcome wiring errors

Devices That Commonly Use Safety Relays

- Emergency Stops

- 3 Position Devices

- Safety Gates

- Pressure Sensitive Mats

- Contact Strips

- Foot Operated Switches

- Time Delay Scenarios

Transcript

[0m:4s] Hi I'm Josh Bloom, welcome to another video in the RSP Supply education series. If you find that these videos are helpful to you, it certainly helps us out if you could give us a big thumbs up and subscribe to our channel.

[0m:15s] In today's video, we are once again going to be talking about relays. But more specifically, we want to talk about safety relays.

[0m:24s] Safety relays are simply electrical devices that function much like a regular relay, but are more specifically designed to implement various safety functions in many different environments.

[0m:39s] If you have not seen our other videos in which we discuss basic relay functionality, we will link those videos in the description below.

[0m:48s] Because safety relays are more complex than normal relays, we will be covering them in two parts. This video will focus on why we use these kinds of relays and in what types of scenarios they are most commonly seen. In part two of this video, we will actually discuss how the relay functions to accommodate the different safety guidelines necessary for various different devices in which they work with.

[1m:16s] So the first question is why do we use these types of relays? As mentioned before, safety relays are specialty relays that are designed to implement various safety functions,

[1m:28s] commonly in plant environments with industrial machinery and motors.

[1m:34s] In the event of a hazard safety relays can help reduce the risk to a much more acceptable level. They are commonly designed to be used in conjunction with other safety relays to increase the functionality and safety levels in work environments. Each safety relay will typically monitor one specific function at a time. So, when they are connected to another safety relay, you can monitor multiple points on one piece of machinery and have many ways to power down the device in the event of a hazard.

[2m:12s] It is very easy to change the combination of how each relay is used with other relays to achieve different results.

[2m:21s] The design and functionality of these relays is not too dissimilar from normal relays,

[2m:28s] with a few exceptions.

[2m:30s] Like a common relay, they use contacts that can be open or closed. However, they add the ability to evaluate electronically and can control outputs on the relay based off of those evaluations.

[2m:46s] They can also be fully electronic in some situations.

[2m:50s] If installed correctly, a safety relay will continue to function if a fault in a device occurs,

[2m:58s] or if a fault is caused by a sensor.

[3m:1s] The redundant designed features of safety relays allow for wiring errors while still providing proper safety function.

[3m:10s] So, where do we commonly see these types of relays being used?

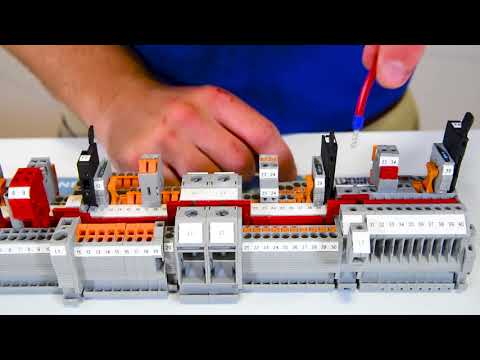

[3m:14s] As mentioned before it is very common to see safety relays being used around industrial machinery where safety is critical.

[3m:23s] Areas such as an industrial manufacturing plant environment, where there are a lot of motors machinery and conveyors all operating simultaneously.

[3m:34s] Some of the common devices that safety relays will be used with are emergency stops, three position devices, safety gates, pressure sensitive mats, contact strips, foot operated switches, and time delay scenarios.

[3m:51s] Safety relays are tested much more vigorously than normal relays and have a much lower failure rate. The contacts are designed so that they can be completely disconnected breaking both sides of the power connection as opposed to just one like many normal relays. In short, they are designed for safety and have many fail safe features and redundancies integrated into their circuitry to ensure the safest possible solutions.

[4m:20s] In the next part of this brief series, we will discuss how these safety relays actually works.

[4m:26s] For a full line of safety relays and thousands of other products, please go to our website. For more information or other educational videos, go to RSPSupply.com, the Internet's top source for industrial hardware. Also, don't forget: like and subscribe.