Terminal_Block_Connection_Types.pdf

Screw Terminal Blocks

The most common connection type, made with a stripped wire and screwdriver. Proven for stringent requirements, including large conductor cross-sections.

Spring Connection Terminal Blocks

The special contact spring allows easy insertion and guarantees a high level of contact quality.

Push-In Terminal Blocks

Easy insertion with push-in connection technology. Conductors from 0.25 mm² can be connected directly without tools.

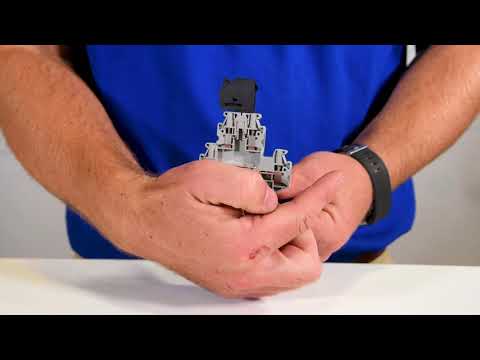

Fast Connection Terminal Blocks

No stripping or crimping required – simply cut the cable to length and it makes contact within seconds.

Barrier Terminal Block

Used where vibration is an issue, typically in rail or transportation industries. Designed for use with spade or ring terminals, secured with a bolt and nut to resist loosening.

Transcript

[0m:4s] Hi I'm Josh Bloom, welcome to another video in the RSP Supply education series. In today's video we're going to be talking about different types of terminal block connection types. More specifically we're going to be focusing on the Phoenix Contact CLIP line terminal blocks. So today we're going to talk about the five different connection types that Phoenix Contact offers with their terminal blocks. The first type of connection is the screw type connection terminal block. That is shown right here. This is the most common type of connection that you'll find with terminal blocks. It's been in the industry for a very long time. You simply use a precision screwdriver to make the connection with a stripped wire. Insert the wire into the terminal port.

[0m:48s] Tighten your screw until your wire has been properly torqued.

[0m:55s] The next type of terminal block connection we're going to talk about is the spring cage connection.

[1m:1s] The benefits of using the spring cage connection are that it's much quicker to terminate and disconnect wires. It's safe, sturdy, and secure, much like the screw type. Strip the wire, insert a precision screwdriver into the spring cage, insert the wire, then remove the screwdriver to secure the connection.

[1m:25s] The next type of terminal block connection is the PIT, or push-in terminal. This is a tool-free connection. Operators can remove and reinsert wires without tools. These require a ferrule for proper seating.

[1m:58s] Insert the wire with ferrule into the terminal until seated. To remove, press down with a screwdriver to release the spring.

The next type of terminal block connection is fast connect. This allows the operator to terminate the wire without stripping insulation. It’s a gas-sealed connection to prevent corrosion. Insert the insulated wire, use a screwdriver to pry the terminal back, and secure the connection.

[2m:52s] The terminal block displaces the insulation to make contact with the wire, creating a secure connection with no tools.

[3m:3s] The last type is the barrier terminal block, often used in rail or transportation industries where vibration is an issue. Wires must have spade or ring terminals crimped, placed over the bolt, then secured with a nut to resist loosening.