Dry_Contacts_vs_Wet_Contacts___The_Basics.pdf

Dry Contacts vs Wet Contacts: The Basics

Hi, I'm Josh Bloom, welcome to another video in the RSP Supply education series. If you find that these videos are helpful to you, it certainly helps us out if you could give us a big thumbs up and subscribe to our channel.

In today's video, we are going to talk about a few common electrical phrases that are often misunderstood with hopes of clearing up and answering any questions you might have about this subject.

I am referring to both dry contacts and wet contacts and what they are and what they mean, and how they are used in the electrical circuitry.

You have probably heard these phrases or at least one of them many different times, especially if you are doing any kind of electrical work on a regular basis. Dry contacts in particular are mentioned quite often, especially in control circuitry. However, both of these types of contacts are used often in many of the different devices we work with on a daily basis.

Again, in this video, we hope to answer some common questions such as: What is the difference between the two types of contacts? Where do we see them being used? And in what cases, does it make sense to use one or the other?

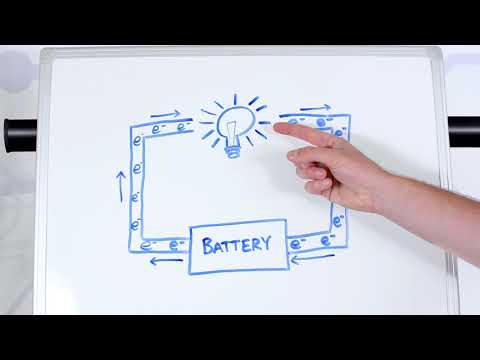

Let's first start with the dry contact as it is probably the more referenced type of contact out of the two. The easiest way to think of a dry contact is to think of a light switch. The switch itself does nothing except open and close. When the switch is closed, power that is being supplied by another source can flow through it. When the switch is open, power is interrupted and can no longer flow.

This is the only purpose of the switch. This in essence is a dry contact. One of the most common use cases of this type of contact is found in a relay.

Relays have a coil that when energized will open or close a set of contacts. Again, when the contacts are closed, power can flow through them to whatever source the power is intended for. But the relay itself is not providing any intrinsic power to the contacts. The power is always being supplied by another source. This is a dry contact, and they are used all over the place, especially in areas where control and automation are being used.

Now let's talk about a wet contact. Wet contacts are different in one main area. The power that is being switched is intrinsic to the device that is switching the contacts. Or in other words, the power flowing through the contacts is coming from the same power source that the controller is using to switch the contact.

For example: a common device we are all familiar with is a furnace in our homes. This furnace is most likely being supplied 120 volts or 240 volts AC power from our home's electrical panel. This power is used to energize everything in the furnace, including the blower and all of the control hardware.

This control hardware will most likely consist of devices such as temperature sensors, airflow sensors, and other devices that are being used to monitor the furnace and the various operations it performs. So when a temperature sensor within the furnace reaches a certain point, the contact might get closed.

This would be a wet contact because the temperature sensor in the controller that is switching the contacts will be using the same power that flows through these contacts once they are closed.

So, just remember with wet contacts, the power is intrinsic to the device switching the contacts, whereas with dry contacts, the power is not intrinsic to the device that is switching the contacts. The power is coming from another source. Remember the light switch.

We hope that this brief explanation has helped clear up some of the questions you might have in regards to this topic. I know that when I first started working in this industry, I was confused every time someone referred to either a wet or dry contact. But with a little knowledge and basic understanding, it is a very easy subject to understand and can also help you a great deal when working with any type of control or automation hardware.

For a full line of industrial control panel hardware and thousands of other products, please go to our website. For more information or other educational videos, go to RSPSupply.com, the Internet's top source for industrial hardware. Also, don't forget: like and subscribe.