Intrinsically_Safe_Barriers__The_Basics.pdf

Transcript:

[0m:4s] Hi I'm Josh Bloom, welcome to another video in the RSP Supply education series. If you find that these videos are helpful to you, it certainly helps us out if you could give us a big thumbs up and subscribe to our channel.

[0m:17s] In today's video, we are going to be talking about an electrical device that is not very common in most of the electrical circuits you may encounter on a daily basis.

[0m:27s] This is because this device is primarily used in areas where there is a potential for an explosive reaction to occur.

[0m:36s] The device I am referring to is commonly called an intrinsically Safe Barrier.

[0m:42s] This name is a general term and depending on the manufacturer of the device that you are using, the specific name can vary.

[0m:51s] Regardless of specific name and manufacturer, they all have the same intended purpose which is to limit the chances of an explosion in highly volatile areas that use control circuitry.

[1m:4s] This circuitry has the potential of sparking in worst case scenarios, causing ignition of the dangerous gases in a given area.

[1m:13s] Intrinsically safe barriers are specifically designed to greatly reduce the risk of this ignition even in the event of a short circuit and or spark of the circuit in question.

[1m:26s] In this video we will briefly go over the basics of how these devices work and how they can limit the risk of ignition in hazardous locations.

[1m:37s] We will also talk about some of the most common applications you can see these devices being used, so let's get to it.

[1m:45s] As mentioned before, when dealing with control circuitry in hazardous areas such as class, one div 1 and class, one Div 2 environments,

[1m:55s] any instrumentation that is being used has the potential to short circuit which can lead to deadly explosions.

[2m:5s] In order to reduce this risk, many safety standards have been put in place that limit the chances of a short circuit, or at the very least can contain the explosive effects into a small area.

[2m:20s] Using intrinsically safe barriers is one of the easiest ways to reduce this risk when working with instrumentation that have power running to them.

[2m:31s] Typically in these types of scenarios, the power that is being fed to the instruments in question is being supplied from a different location. A location that is not at risk of explosion if a short circuit occurs. However, in order for the instruments to function in these more dangerous and volatile environments, power must be sent to them.

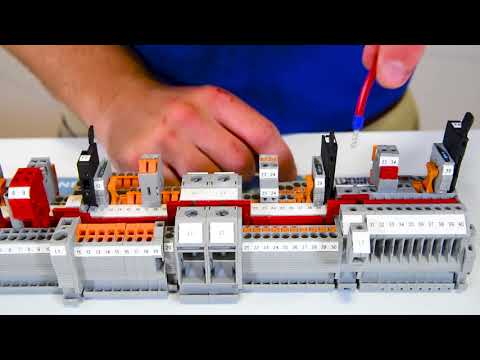

[2m:54s] Intrinsically safe barriers work by using a combination of resistors and Zener diode to limit the amount of voltage and current that is being sent to devices and instruments in these hazardous areas.

[3m:9s] The goal of limiting this power is to ensure that in the event of a short circuit. The energy created by the short circuit is low enough that it falls below what is known as the ignition curve of the gas mixture in that particular area. The ignition curve simply represents the amount of voltage and current that is needed to ignite a certain gas mixture.

[3m:35s] This ignition point can vary greatly depending on the gas, mixture and concentration of gas. Because there are several different variables that dictate when gas will ignite, intrinsically safe barriers needs to be purchased with a specific application in mind.

[3m:54s] They are not intended for a one size fits all type of scenario. So, make sure that before you purchase your barrier that you have a very firm understanding of the area in question, and know what the ignition curve is, and what the power requirements of the instruments you are using are. With this information, you will be able to make sure you purchase the correct advice for your specific scenario.

[4m:20s] Intrinsically safe barriers are most commonly used in areas where this explosive potential is high, as we have already mentioned. So, areas such as refineries are a very common place you might find these devices being used. Also power plants, especially those plants that use chemicals to generate energy, as well as weight water treatment facilities where large amounts of methane and other gases are created and used is an optimal place to use an intrinsically safe barrier.

[4m:50s] What is important to remember when using one of these devices is to first and foremost, do everything you can to limit the need for any instrumentation and control hardware in these areas. However, once you are certain you have established a need, make sure to review the specs of the instrumentation being used to gain a clear understanding of the power requirements, and then learn what the ignition curve in that area that the instruments are going to be located in will be.

[5m:19s] Once you have this information, you can determine the intrinsic safe barrier. That is needed for that specific application.

[5m:27s] Remember, these barriers are used as a last line of defense. Proper, planning and good foresight can help you eliminate most of the potential issues you might encounter in these dangerous areas. For a full line of intrinsic safe barriers and thousands of other products, please go to our website. For more information or other educational videos go to RSPSupply.com, the Internet's top source for industrial hardware. Also, don't forget: like and subscribe.