Differences_Between_Relays_and_Contactors.pdf

Much like a relay, a contactor is an electrically controlled switch. They both are commonly used in industrial and commercial applications, and function in almost the exact same way. The still use a coil, that when energized, will close the contacts allowing current to pass through. The main difference between contactors and relays are the loads that they are intended to handle.

Relays

- Relays are typically used in circuits that have a maximum load current rating of 20 amps, but most of the time are not used in circuits that require more than 15 amps.

- Normally only used in single phase applications.

- They are mainly used in lower voltage automation, control and safety circuits and are typically switching smaller electrical loads.

- In many cases a relay will have both a normally open and normally closed contact.

- Smaller in size.

Contactors

Contactors are typically used for switching loads that draw a much higher current.

- Motors

- Capacitors

- Lighting Systems

Can be used to switch loads with current anywhere from 20a – 12500A.

Normally consist three separate contacts designed for used in three phase power applications. You won’t normally find a normally closed contact on a contactor, they typically function with just a normally open set of contacts. So, the function in some ways is more simplified the many relays.

In many cases they also have auxiliary contacts which can be used to monitor the state of the contactor. For example, if the contact is open or closed.

In some cases (depending on the contactor) they can offer arc suppression, thereby increasing the safety of higher voltage load switching.

They do not offer short circuit or overload protection. Those functions require additional devices.

Transcript

[0m:4s] Hi I'm Josh Bloom, welcome to another video in the RSP Supply education series. Today we're going to be talking about the differences between contactors and relays. Relays and contactors function in almost the exact same way. They both rely on a coil that one energized allows contacts to be closed which allows current to pass through. For more information about how they actually function, please see our other videos. We'll link those in the description below. So although there are many similarities, the main differences between contactors and relays are the loads that they're actually intended to handle. Let's first talk about relays. Relays are typically used in applications where the load current rating is no more than 20 amps. However, typically we see those used in applications of no more than 15 amps. They are most commonly used in single phase applications, so they are going to be mostly seen in lower voltage situations such as safety and automation systems. Most relays are normally sold with both normally open and normally closed configurations. This allows us to control multiple circuits with one relay.

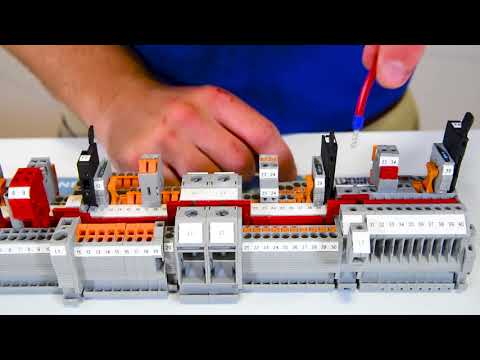

[1m:9s] Relays are also typically going to be much smaller than most contactors. So now that we know some of the basic features that make up a relay, let's talk about some of the things that make contactors a little bit different. Contactors are designed for switching loads that draw much higher current such as large motors or fans, lighting systems, capacitors, et cetera.

[1m:30s] Most contactors are designed for use in three phase applications. This requires three separate conductors to run through our contactor. However, we can use one or two of the contacts in our contactor for single phase applications. Most contactors typically come with a set of auxiliary contacts. This allows us to monitor the state of the actual contactor itself, whether it's open or closed.

[1m:55s] In some cases, depending on the contactor in higher voltage situations, they can also offer arc suppression which can increase the safety level of our contactors. However, keep in mind that contactors don't offer any kind of overload or short circuit protection. Those devices are typically sold separately. So, again, let's quickly look at the comparison between the two. So, with relays, we have a lower current or maximum of 20 amps whereas contactors can run all the way up to 12 500 amps. Relays are typically used in single phase applications whereas contactors are more commonly used in three phase applications.

[2m:33s] Relays are commonly used in lower voltage situations where contactors are more likely to be used in higher voltage situations.

[2m:40s] Relays give us both a normally open and normally closed contact depending on the relay where contactors give us three sets of normally open contacts.

[2m:50s] Relays are typically much smaller than contactors and some contactors also offer arc suppression in higher voltage situations. For a full line of relays and contactors and thousands of other products, please go to our website. For more information or other educational videos, go to RSPSupply.com, the Internet's top source for industrial hardware. Also, don't forget: like and subscribe.